Quality Inspection At Various Stages

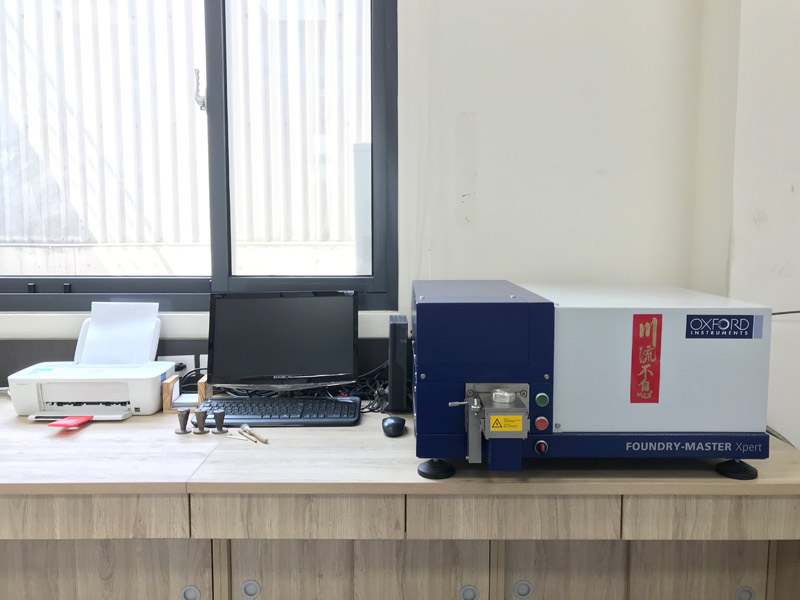

- Raw material input inspection: iron milling, coke, sand core, silicon manganese ... etc.

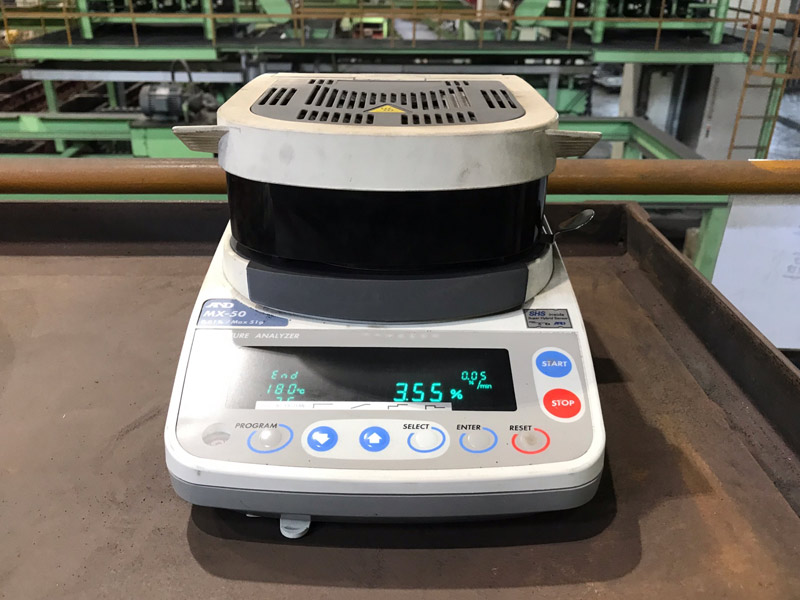

- Sand mixing operation: sand mold hardness, moisture ... etc.

- Casting operation of iron furnace: pouring temperature, carbon and silicon value inspection (CE value).

- Inspection before furnace, pouring inspection, white mouth inspection before furnace, metallography of casting, material, hardness, tensile strength, etc.