Production Capacity

Si Den has accumulated more than ten years of casting experience and is a professional manufacturer of grey cast iron casting and precision processing. It accepts various commissions from customers and casting related products. Gray cast iron has good workability, vibration control and wear resistance, and is suitable for general industrial machinery. We are committed to solving casting related problems for our customers and providing high-quality products.

Medium frequency induction furnace melting operation:

bottom coke control, coke-iron ratio temperature control, raw material mixing ratio, FC mixing ratio adjustment control, furnace building operation, various inspection records.

Medium frequency induction furnace melting operation:

bottom coke control, coke-iron ratio temperature control, raw material mixing ratio, FC mixing ratio adjustment control, furnace building operation, various inspection records.

Medium frequency induction furnace capacity: 3 tons/50 minutes

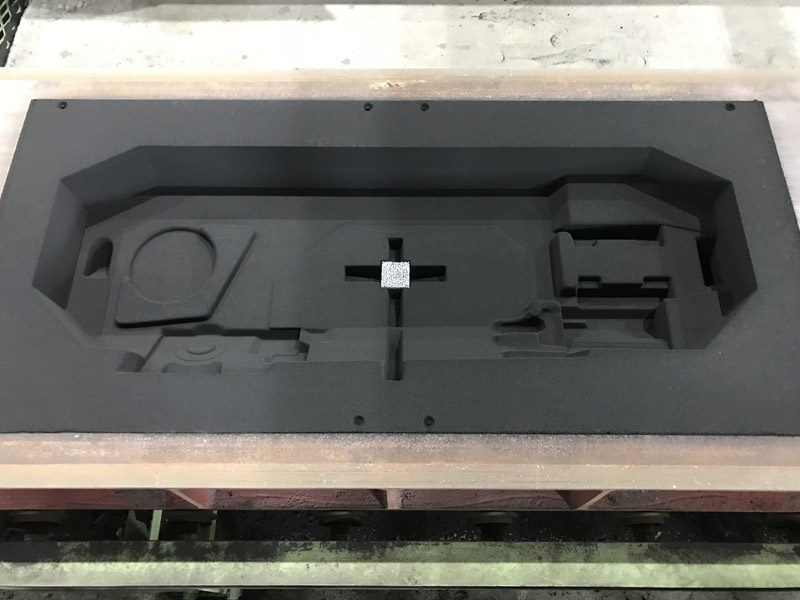

Sand-matching modeling operations:

sand processing operations, sand-distribution and sand-distribution ratio control, mixing and kneading operations, humidity and viscosity control, sand-distribution adjustment, sand-distribution engineering and sand-distribution quality control.

sand processing operations, sand-distribution and sand-distribution ratio control, mixing and kneading operations, humidity and viscosity control, sand-distribution adjustment, sand-distribution engineering and sand-distribution quality control.

Maximum unit weight for semi-automatic moulding: 100 kg

Maximum size for semi-automatic moulding: 2.2x1.2M

Maximum unit weight for

automatic moulding : 80 kg Automatic moulding capacity: 40 moulds/1 hour

Automatic moulding size: 1280x600mm

Maximum size for semi-automatic moulding: 2.2x1.2M

Maximum unit weight for

automatic moulding : 80 kg Automatic moulding capacity: 40 moulds/1 hour

Automatic moulding size: 1280x600mm

Pouring operations:

potting operations, pouring temperature time control, slag removal operations.

potting operations, pouring temperature time control, slag removal operations.

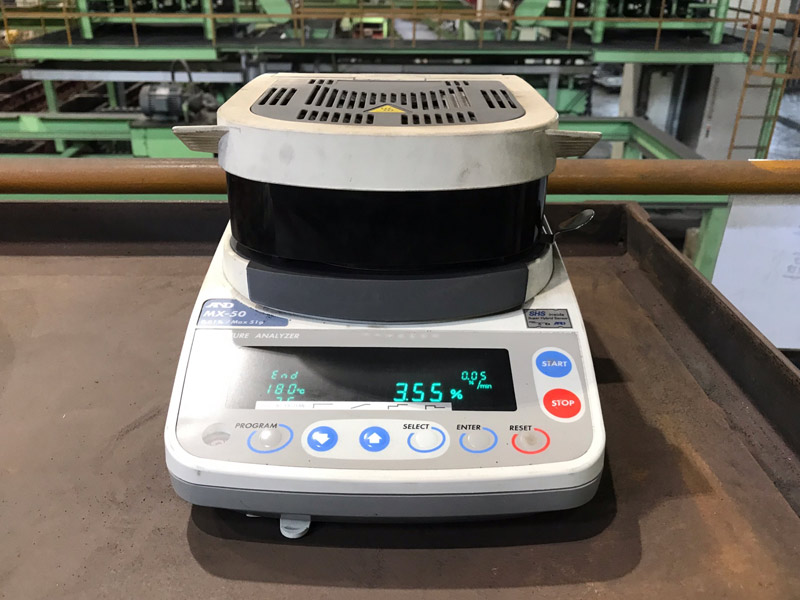

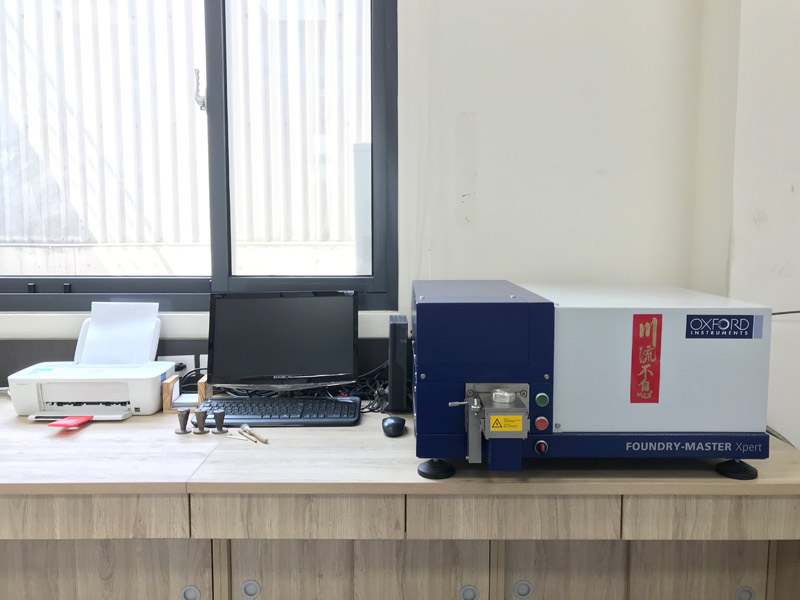

Material control operations:

chemical composition FC grade control, feeding element ratio control, tensile strength and hardness test, metallographic structure test.

chemical composition FC grade control, feeding element ratio control, tensile strength and hardness test, metallographic structure test.

Post-processing operations:

box-turning operations and time control, sand mold removal operation control, sand washing and sand removal operation control, edging and trimming operations, drilling and tapping processing.

box-turning operations and time control, sand mold removal operation control, sand washing and sand removal operation control, edging and trimming operations, drilling and tapping processing.